THE FREESTANDING BATHTUB

No other fixture harkens tradition and romanticism like a claw foot tub. Once common among the wealthy during America’s Gilded Age, the freestanding bathtub fell into obscurity during the second half of the twentieth century.

As indoor plumbing became widely available and home construction took on a more volume-driven approach, the freestanding tub was eventually supplanted by the more common alcove tub we are accustomed to seeing today. Many of the new homes constructed after WW2 were small by today’s standards, and allowed for only a single bathroom. The alcove tub, typically installed between walls covered with tile, allowed people to utilize it for both bathing and showering; important for home designs where cost, construction, and space considerations drove the market for volume home building.

Consequently, bathroom time became a utilitarian activity – it would be difficult to spend an hour soaking when there are 4 other people waiting to use the bathroom.

In recent years, consumers have striven to invest in their own wellbeing. Modern home designs allow for space and amenities unimaginable in the post war era. Many people have revisited the freestanding tub as a means of seeking refuge from their daily life. New materials and manufacturing techniques have introduced a wide array of options – fulfilling virtually every budget and design consideration.

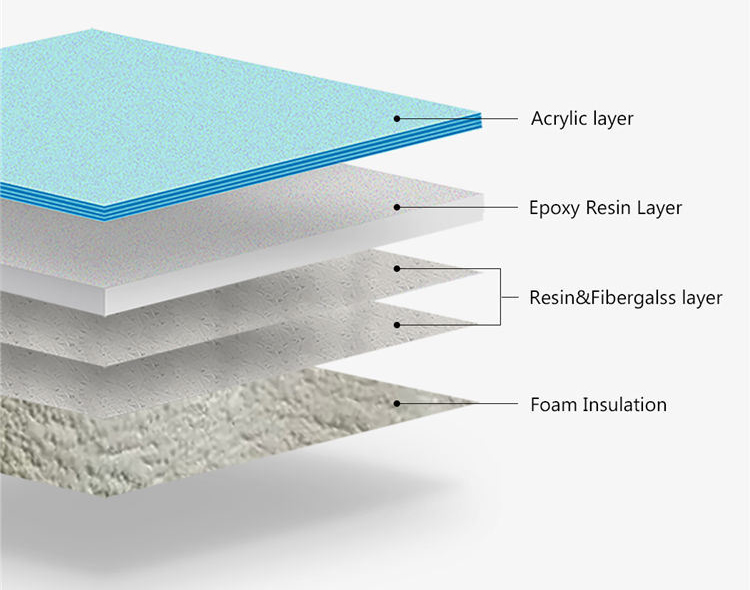

ACRYLIC FREESTANDING TUB

Acrylic has been used in bathing and showering applications for almost 50 years. A time-tested, cost effective material, it offers affordability and durability coupled with an ability to be molded into shapes and designs that are impossible with cast iron. Acrylic is also a repairable material; minor scratches or chips can be fixed by a professional. This is not possible with enameled cast iron where the enamel surface is melted on to the hot cast iron during the manufacturing process. Acrylic tubs can be found in two distinct designs:

- One-piece; the tub and it’s exterior are constructed from a single, continuous piece of molded acrylic.

- Two-piece; the tub bathing well and skirt are formed from two different pieces.

One-piece acrylic tubs are an excellent option for those seeking an aesthetically pleasing, cost-conscious design. Their “seamless” nature gives a solid feel, with very little deflection which is a common issue in less-expensive, two-piece tubs. They are relatively lightweight, around 100 lbs, making installation far easier and less labor intensive than a cast iron alternative. The most common nightmare among contractors in our industry is that a customer selects a cast iron tub for their second story bathroom remodel job. They’ll price the job accordingly. Just food for thought.

The two-piece design is the least expensive option. Constructed of an acrylic bathing well, which sits inside either a fiberglass or acrylic skirt, these tubs are primarily selected due to their low price, and easy installation. While they lack the “solid” feel of a more expensive, one-piece design, they still offer the ease of maintenance, and longevity of acrylic. One benefit these tubs have over a cast iron or one-piece acrylic design, is that they will usually accommodate a deck mount faucet. The pipes supplying water to the faucet are concealed between the inner and outer shell. Deck mount faucets are far less expensive than floor-mount faucets.

CAST IRON FREESTANDING TUB

Traditionally constructed of enameled cast iron, early claw foot tubs were both heavy and expensive; and were far out of reach of most consumer’s budgets. But cast iron has a unique property that makes it ideal for a bathtub – it has a very high volumetric heat capacity.

What this means, is once the tub is full of hot water, the water will stay warmer, longer. Combined with the enamel’s glass-like hardness, you have a tub with excellent thermodynamic properties and a durable, low-maintenance surface. The longevity of an enameled cast iron tub is unparalleled even among modern materials. It’s not uncommon for these tubs to last 50+ years.

The drawbacks are the weight (usually around 400+ lbs) and their high cost. Kohler is the only domestic manufacturer operating a cast iron foundry, so the prices of these tubs are high. Less expensive, imported models can be found, but their quality is dubious and the after sales support is often lacking. Due to the semi-permanent nature of a cast iron tub, it’s strongly advised to stay with a reputable brand like Kohler where warranty recourse is available.

MOLDED COMPOSITE FREESTANDING TUB

A newcomer to the bathing world, composite freestanding tubs are the latest in bathing material technology and offer some interesting advantages over other materials. These tubs start out as a liquid slurry of a stone based material mixed with an acrylic or other polymer biding agent. This slurry is pumped into molds and formed to shape under heat and pressure. What results, is a completely homogenous material that offers rigidity, high heat capacity, and a “renewable” surface that can be repaired in the event of damage. While not an inexpensive option, most models cost less than a domestically manufactured cast iron equivalent while weighing substantially less but offering good heat capacity. Available in a wide variety of styles, options can be had to fit both traditional and modern bathroom designs.