“Our experience(s) with Central have been efficient and cost effective. The staff is extremely knowledgeable of all products and can provide design drawings to assist in decision making. The friendly and knowledgeable staff is patient (which is very rare) and accommodating to ensure you procure everything needed for a successful project. Personally, I only shop at a supply house and not a big box store, the best price and service is always present. If an issue with any product exists, you merely take it back to Central and they resolve immediately. A big box store requires you call the manufacturer to resolve issue, that can take weeks or months.”

Types of Heating Systems

A heating system, fundamentally, is a way of generating heat in one location, typically through the combustion of natural gas, propane, fuel oil, or wood, and transporting that heat via a “medium” to another location. The three key components are 1) a heat generating source (a boiler for hot water or steam systems or a furnace in the case of hot air systems); 2) a system of conduit to transport the heated medium (pipes for hot water or steam and ducts for hot air); 3) an emitter to project the heat into the desired space (baseboard for hot water, radiators for steam, or registers for hot air). There are benefits and drawbacks to each type of system, which we will explore below.

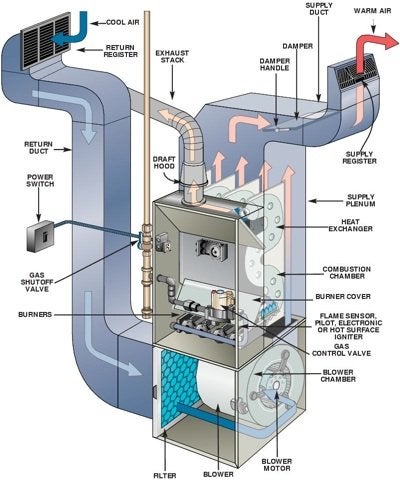

Forced Hot Air Heating

By far the most commonly encountered type of heating system, forced air relies on heating air with a furnace, distributing that air via a system of metal ducts, where it ultimately finds its way into the living space through an outlet called a register. A benefit from the duct work is that it provides the necessary infrastructure for both heating AND cooling; the central air conditioner distributes cool air through the same ducts. This is why forced air systems are typically encountered in areas with a wide seasonal temperature range. While convenient and cost-effective, there are some drawbacks that should be mentioned.

Air makes for a poor heat transport medium – due to its gaseous nature, it has very low density and mass per unit of measure, meaning its “heat carrying ability” is limited. In order to distribute a respectable amount of heat, a large volume of air needs to be moved at a relatively high temperature. The average air temperature generated by a furnace is between 120 – 140 Degrees F and the average velocity is around 300 fpm (feet per minute). This is why ducts are much larger than pipes, which would be used to transport the heat via hot water in a hydronic heating system. The size of the ducts and their placement during construction must be considered. Conventionally-framed, otherwise known as “stick-built”, is the most common method of home construction and allows for the concealment of ducts within the walls and floors. This is not the case with “post and beam” type home construction where the exposed nature of the frame structure makes it difficult to conceal duct work.

Another drawback of forced air is it’s “convective quality”. The heated air is blown through the duct work and into the room. While doing so, the heat leaves the register, and makes it way to the ceiling (hot air rises by nature and this is exacerbated by the velocity inherent in this type of system). Overall, this is a relatively inefficient means of heating; heating a space works best from the ground up (see radiant heat section). Most of the energy is wasted by heating the ceiling area, and not the floor level where’s it’s needed. The convective nature also allows for allergens, dust, and other particulate matter to be blown around the room.

Forced air systems are notorious for their “hot and cold” spots. This is mainly due to the difficulty in zoning such system. Zoning refers to the ability to discretely control the heat output in various areas encompassed in the overall system.

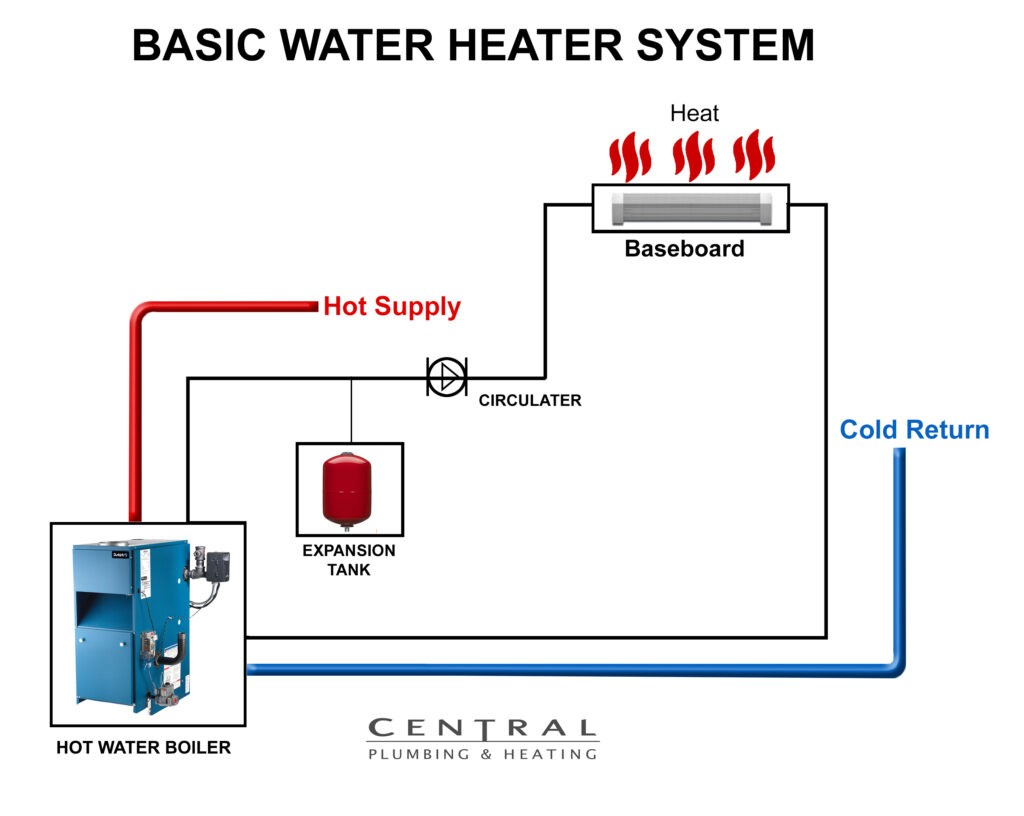

Hydronic heating. What exactly does this mean? Hydronics is the use of water, be it in a liquid or gaseous (steam) form, as a medium to transfer heat. The water is heated in a boiler, and distributed via a system of pipes. Water has some interesting qualities that make it a far superior heat transfer medium compared to air. It’s denser (more mass) and consequently has a higher “heat capacity”. In fact, water has one of the “highest specific heat capacities among common substances”. It’s also plentiful and non-toxic. We’re lucky to have such a beneficial resource!

Hot water systems are highly adaptable and can be categorized around three basic design theories: – 1) high-temperature, low-mass; 2) high-temperature, high-mass; and 3) low-temperature, high-mass.

A high-temperature, low-mass design would be your basic hot water baseboard system. Hot water, usually around 180 Degrees F is circulated through the pipes to the baseboard heat emitters. The baseboard itself is composed of a length of copper pipe, wrapped with aluminum fins, all of which is enclosed in a metal housing. As the hot water moves through the pipe, heat is transferred to the aluminum fins by conduction (both copper and aluminum are highly conductive metals, hence their use in this application). The baseboard enclosure is designed to foster a slight convective current with the surrounding air – as the fins heat up, the warm air rises out of the top, drawing the cooler room air through the bottom. There is a small amount of heat energy dissipated into the room by means of radiation, but the vast majority is due to the convective nature of the baseboard design. As opposed to the “active” convection inherent in a forced hot air system, a baseboard system’s convection is very subtle, and not prone to distributing particulate matter. Hot water systems are an excellent choice for those suffering from allergies.

A benefit of the high-temperature, low-mass system is it’s rapid response rate to heating demands; the high temperature of the water quickly heats the lightweight baseboard assembly; expediting the heat transfer into the room. In hybrid hot water systems, such as those composed of a mixture of radiant heat and baseboard, the baseboard is typically installed in areas that are seldom used, like spare bedrooms and offices, where a rapid increase in temperature would be desired.

From a cost perspective, hot water baseboard systems are less expensive to install compared to forced air systems; duct work is more labor intensive than pipes. But if central air conditioning is being considered, forced air offers the additional benefit of having a preinstalled infrastructure.

High-temperature, high-mass systems are somewhat unique. They are composed of radiators (a high mass type of emitter) supplied with water temperatures between 150 – 180 Degrees F. Commonly found in Europe, hot water radiators are rarely used in the United States, and most of these types of designs are usually converted steam systems in older homes. While still an effective form of home heating, harboring all the aforementioned attributes of hot water systems, radiators are bulky and considerable design concessions have to be made when room layout is considered.

This now brings us to the low-temperature, high-mass hydronic system. Most commonly found in the form of radiant heating, this genre of design offers unparalleled levels of comfort and efficiency.

Radiant heat has been used for centuries. The earliest known form was used by the Romans who called it hypocaust

The hypocaust was composed of a “furnace” (basically a stove burning wood) and a series of hollow chambers beneath the floor of the living space. Heated air from the stove found its way through these spaces, and eventually up and out of the home through a chimney system. While not an efficient means (refer to the drawbacks of utilizing air as a heat transport medium) of heating, the basic principles behind this design would eventually find their way into modern radiant heat systems which utilize water as the heat transport medium.

Radiant heat, in its modern form, utilizes relatively low temperature water (approximately 100 Degrees F) circulated through an array of tubes adhered directly underneath, or imbedded, in the floors of the living space. Unlike baseboard systems, which primarily rely on convection, the heat from the hot water is CONDUCTED through the pipe and directly into the floor. The warm floor then warms all the objects in the room, people included. You end up with a completely silent, even, means of heating a space through the two most efficient methods possible – conduction and direct radiation. Infrared photographs of rooms heated with radiant systems show the highest level of heat energy at the floor level. The floor itself acts as a giant radiator, relying on it’s high mass to radiate heat in the primary living space of a room; very little energy is wasted in heating the ceiling area (a drawback of forced hot air systems).

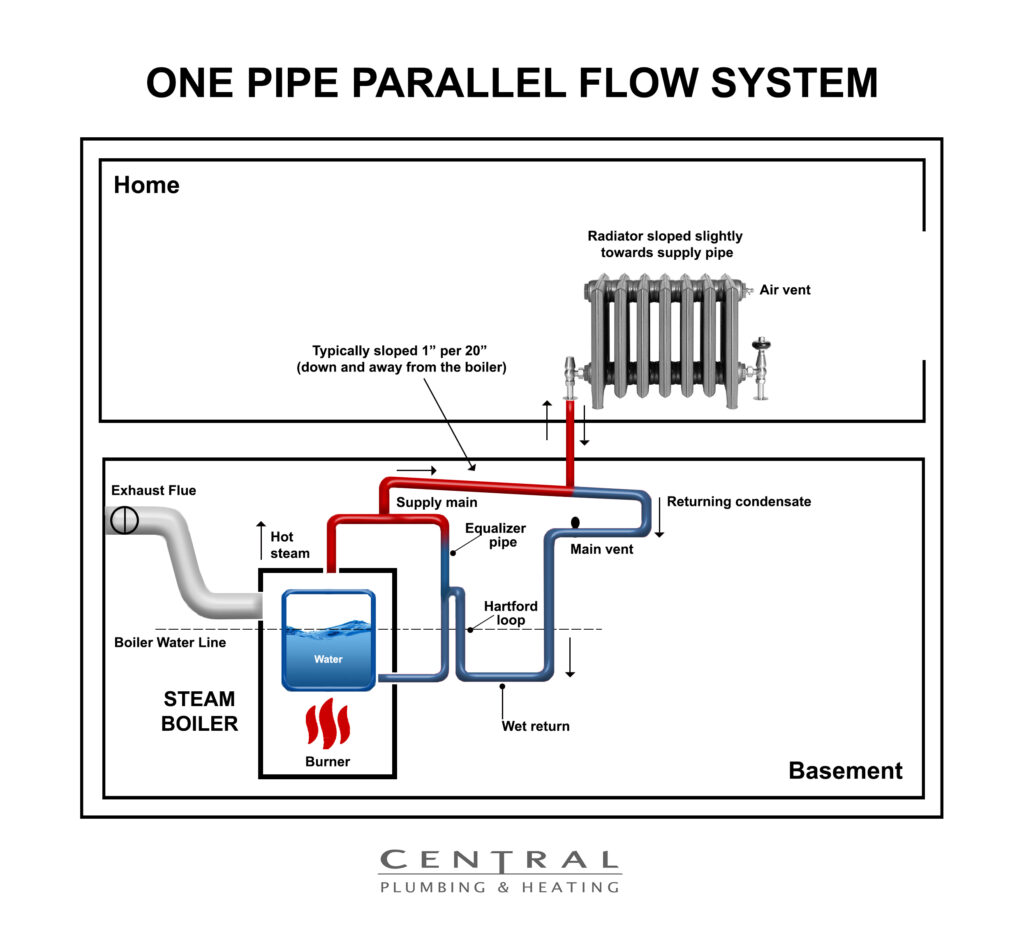

Steam Heating Systems

Steam is probably the most fascinating type of heating system. By utilizing the unique nature of super-heated water, turned into a gas, the physics behind this help to enhance the heat transfer to the emitters (radiators). Steam systems are a type of high-temperature, high-mass system and their primary benefit is found in the heat transfer ability due to the latent heat stored within the steam. Residential steam systems are a type of “semi-open” heating system. Liquid water fills approximately 2/3 of the boiler, with a space above for the accumulation of steam during the heating cycle. This is different from the typical hot water system, which is completely filled with liquid water; void of any air. With a steam system, the liquid exists in three forms – 1) as a liquid in the boiler; 2) as saturated steam above the liquid water during the heating cycle; 3) as condensate after the hot steam has transferred its energy into the radiator.

During operation, the boiler heats the water until the boiling point. As more heat energy is absorbed by the water, and the molecules are excited, steam begins to build in the empty space above the water level. As the steam makes its way through the pipes, displacing the air in the system, small vents on the side of the radiators allow for the air to evacuate.

Those who have lived with steam systems will know this sound by heart – a hissing sound. The heated steam makes its way into the much cooler radiator. This is where the magic happens. When the water was heated in the boiler to make steam, it underwent what’s referred to as a “phase transition”. In this case, the steam (existing as a gas) has potential energy in the form of “latent heat” and when it comes in contact with a cool surface, it condenses, releasing this energy into the radiator, and ultimately the room. This stored “extra” energy allows a much higher efficiency of heat transfer versus the heat transfer means (conduction) typically found in a static-state hot water system. The order of magnitude is in fact several times greater.

Steam systems are no longer installed in new home construction. They were most prolific during the early part of the 20th century when homes were poorly insulated. The high-mass nature of radiators, coupled with the extreme amount of heat energy found in steam, allowed for the radiators to absorb this energy, and slowly release it into a room even after the system’s demand was satisfied; offsetting the homes heat loss due to the lack on proper insulation in the walls and ceilings.